Follow Us

“There is no best, only better” are not just words to us but a way of life. We are able to better meet and exceed your diverse product needs by providing designs that are exactly suited to your requirements. Your satisfaction is our motivation.

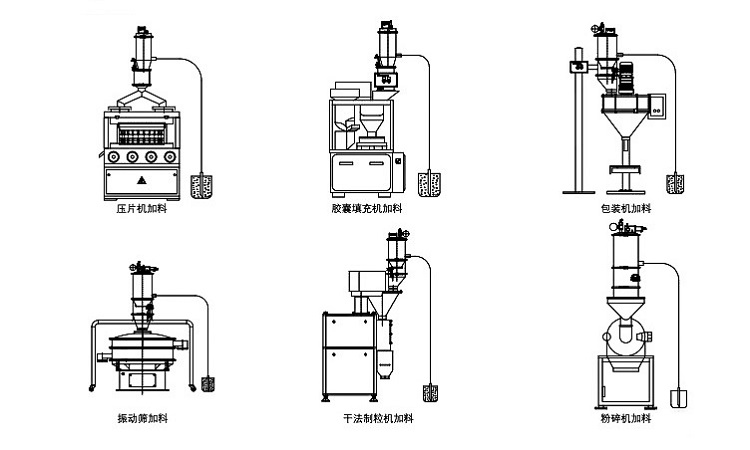

Image Description: Schematic Diagram of Vacuum Conveyor Feeder.

Image Description: Schematic Diagram of Vacuum Conveyor Feeder.

Reviews

There are no reviews yet.