Automatic Overflow Filling Machine

Automatic Overflow Filling Machine (Automatic Liquid Filler) adopts constant pressure fixed flow channel parameters, and controls the filling time to realize different metering filling.

The bottle styles can be changed without changing the fitting parts. It is used in the fill a wide range of water-thin to low-viscosity liquid without gas. Such as, juice, soy sauce, vinegar, edible oil, oral liquid, disinfectant, pesticide, chemical, detergent, lubricating oil, cosmetics, and so on.

Advanced Technology

- 1. This automatic overflow filling machine has been integrated with the international design concept and appearance model.The pneumatic components of the whole equipment are controlled by well-known pneumatic components PLC.

- 2. The filled liquids are accurated, no bubbles, no dripping. 40-1000ml applicable to a variety filling of bottle-shaped (included shaped-bottles).

- 3. Convert different bottles within 10 minutes.

- 4. Convert different liquid specifications without adding any equipment, just make adjustments to complete.

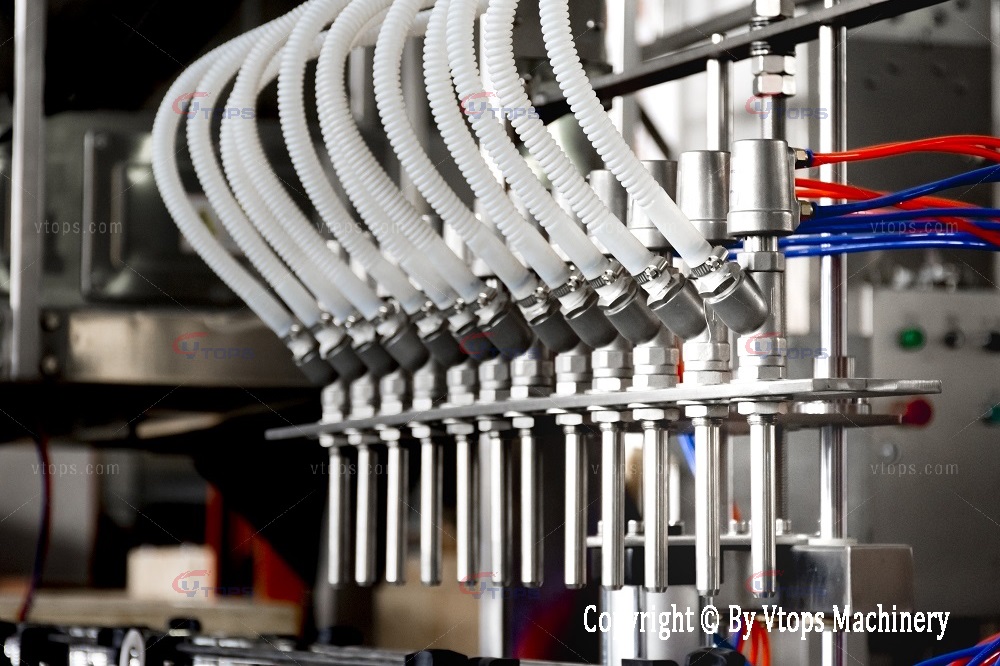

- 5. Each filling nozzle are equipped with a hold bottle device to ensure accurate alignment of the filling injection.

- 6. It adopts anti-drip and wire drawing filling head to ensure the filling. Bottle mouth positioning and no pollution.

Precised Metering Control

- 1. Each filling nozzle can be adjusted separately to achieve precised control.

- 2. The filling time can be accurate to 0.01, which can control the measurement error within ±1%, reduce unnecessary material loss and improve user economic benefits.

- 3. The machine sets the bottle counting program, no bottle, the counting is not in place, and the filling is started only when the number of bottles recorded by the counter matches the set number of filling bottles.

- 4. the amount of filling, you can make the initial adjustment to the required filling amount, and then fine-tuning, you can get the ideal filling measurement accuracy.

Technical Parameters

| Model | VTOPS-L4 | VTOPS-L6 | VTOPS-L8 | VTOPS-L12 | VTOPS-L16 |

|---|---|---|---|---|---|

| Brand | VTOPS | VTOPS | VTOPS | VTOPS | VTOPS |

| Measuring range | 40 – 1000 ml | 40 – 1000 ml | 40 – 1000 ml | 40 – 1500 ml | 40 – 1500 ml |

| Filled Error | ≤± 1% (>100ml) | ≤± 1% (>100ml) | ≤± 1% (>100ml) | ≤± 1% (>100ml) | ≤± 1% (>100ml) |

| Output | 900 BPH | 1500 BPH | 2400 BPH | 3600 BPH | 4800 BPH |

| Contained Conveyor Belt | 4 meters | 4 meters | 4 meters | 6 meters | 6 meters |

| HMI | LCD Touch Screen | LCD Touch Screen | LCD Touch Screen | LCD Touch Screen | LCD Touch Screen |

| Control System | PLC | PLC | PLC | PLC | PLC |

| Air Pressure | 0.5 – 0.7 mpa | 0.5 – 0.7 mpa | 0.5 – 0.7 mpa | 0.5 – 0.7 mpa | 0.5 – 0.7 mpa |

| Gas Consumption | 200 L/t | 200 L/t | 200 L/t | 400 L/t | 400 L/t |

| Power | 1.0 Kw | 1.0 Kw | 1.0 Kw | 1.5 Kw | 1.5 Kw |

| Weight | 260 kgs | 260 kgs | 260 kgs | 400 kgs | 400 kgs |

| Dimensions (cm) | 400 × 80 × 210 | 400 × 80 × 210 | 400 × 80 × 210 | 600 × 83 × 220 | 600 × 83 × 220 |

Working Video

* Video of 12 nozzles automatic overflow filling machine showing from 40th second to 75th second.