40,000 m2 Factory

Up to 2-Year Warranty

Dozens of Patents

Capping machines also named cappers. They are used for the application of plastic and metal threaded caps as well as plastic snap caps, some fitments and some types of corks and plugs.

Capping machines differ in terms of applications and features. Some cappers are designed for industrial or general packaging operations. Others designed for agricultural, chemical, cosmetic, or food and beverage processing applications.

The Screw Spindle Capping Machine gets its name from the spindles it uses to tighten the caps onto the containers. Spindles are vertical rotating shafts that mostly utilizes sets of spindles or rubber wheels grip the cap and container simultaneously, applying torque to twist and tighten the cap.

Therefore, in some cases, we prefer to call the spindle capping machine by the number of rubber wheels, such as an 8-wheel capping machine. It is one of the most popular automated capping machines for screw-type caps cause it is versatile and available to fit many different threaded caps.

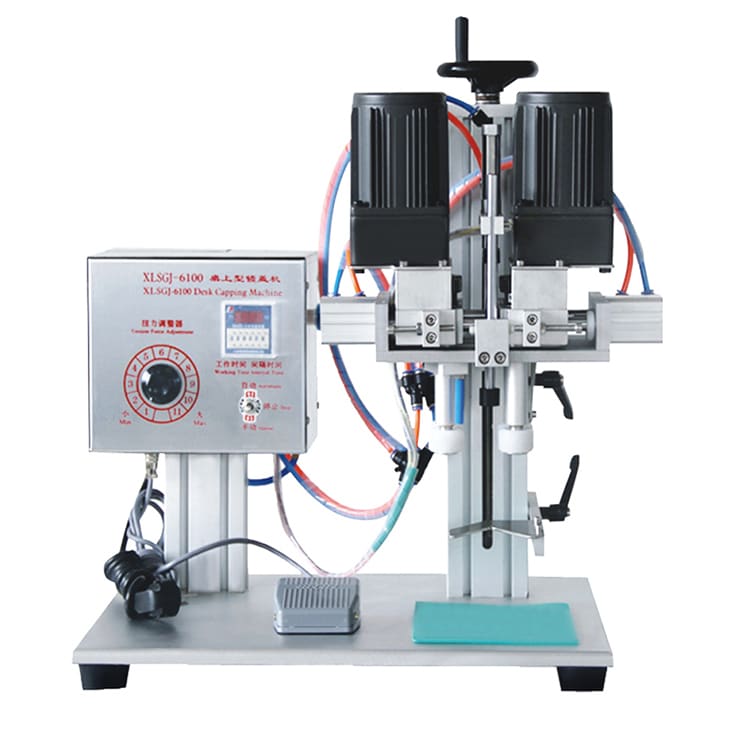

A Screw Chuck Capping Machine uses a chuck head to descend and apply torque to tighten caps securely onto their respective containers. The chuck head is a critical component of the capping machine and is designed to grip the cap and apply the necessary force to ensure proper sealing.

Chuck capping machines use the latest technology to automatically place and accurately torque most cap types onto most bottle types. The chuck capping machines can place and torque flat caps, oval caps, flip top caps, pull spouts, safety caps, child proof caps, sport caps, and caps with over-caps or induction seals. The chuck capping machines can handle almost any bottle type or shape including PET, PP, PVC, HDPE, LDPE, and Glass.

A Glass Jar Vacuum Capping Machine is a specific type of capping machine designed to apply vacuum caps or closures to glass jars. These machines are commonly used in the food and beverage industry, particularly for products like jams, sauces, pickles, and other preserves. The vacuum capping process helps create a tight seal, which is essential for maintaining product freshness and extending shelf life.

A Snap Pressing Capping Machine is a specific type of capping machine designed to apply snap-on caps or closures to containers. Snap-on closures are commonly used in industries like beverage bottling, cosmetics, personal care products, and certain types of food packaging. The snap pressing capping machine is designed to efficiently and securely press these caps onto the containers.

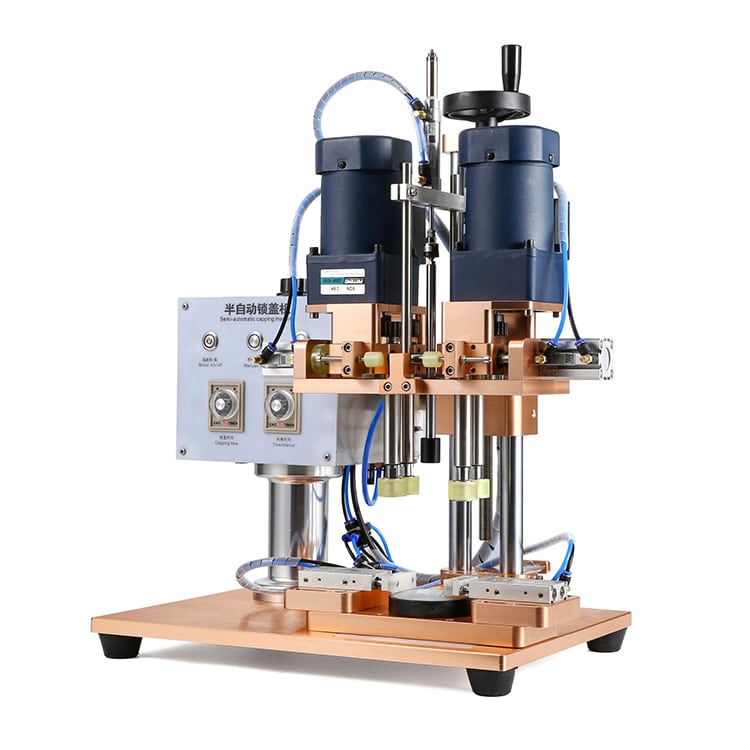

A Semi-Automatic Capping Machine is a type of capping machine that combines automated and manual operations to apply caps or closures to containers. It is well-suited for small-sized production volumes where some level of automation is desired, but full automation might not be necessary or cost-effective.

How Can a Capping Machine Benefit Your Business?

Capping Accuracy

Firstly, the capping machines will speed up capping and improve capping accuracy. The capping procedure may be automated, ensuring that each lid snaps into place perfectly. Capping bottles at a faster pace increases productivity. Because of this, you’ll be able to meet or exceed market demand.

Cross-pollution

Secondly, human mistake is common when items are handled by hand. Moreover, it is tiresome and time-consuming to sift and snap caps into position over and over again. At some time, the individuals performing the work will be exhausted and worn out. And the labor will inevitably contaminate the caps and even the product inside the bottle.

As a result, there is the potential for expensive mistakes to be made. Therefore, capping machines help to minimize contamination. As a result, there is less likelihood for contamination of the cap.

Increase Productivity

Thirdly, engaging in a capping machine as a company is a smart move to enhance return on investment while saving on extra costs. The expense of acquiring and putting up the essential infrastructure might be prohibitive. Your investment will pay off sooner, though. Because hand capping is both costly and unsustainable, this is the reason. Automated capping machines are more efficient than employing many individuals to do physically demanding tasks. People will be able to focus on more essential duties since you will have freed them from tedious physical labor.

Adaptability

Reliable & Dependable

What is a Capping Machine?

A capping machine is a machine that tightens or secures a container’s cap.

How Does The Capping Machine Work?

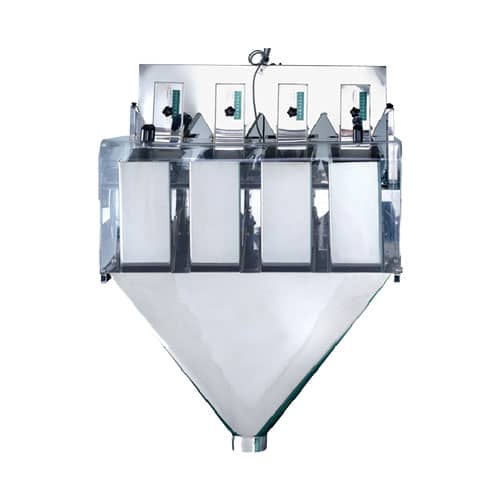

- Step 1: Caps Delivery Caps Delivery has two basic types of systems used to place the caps. One is the pick and place the caps manually. The advantage of manually placing caps is that it is not limited by the form and style of the lid. The other one is picking and placing the caps by machine or robot. The advantage of this method is a high degree of automation, less contact with people, and more sanitation.

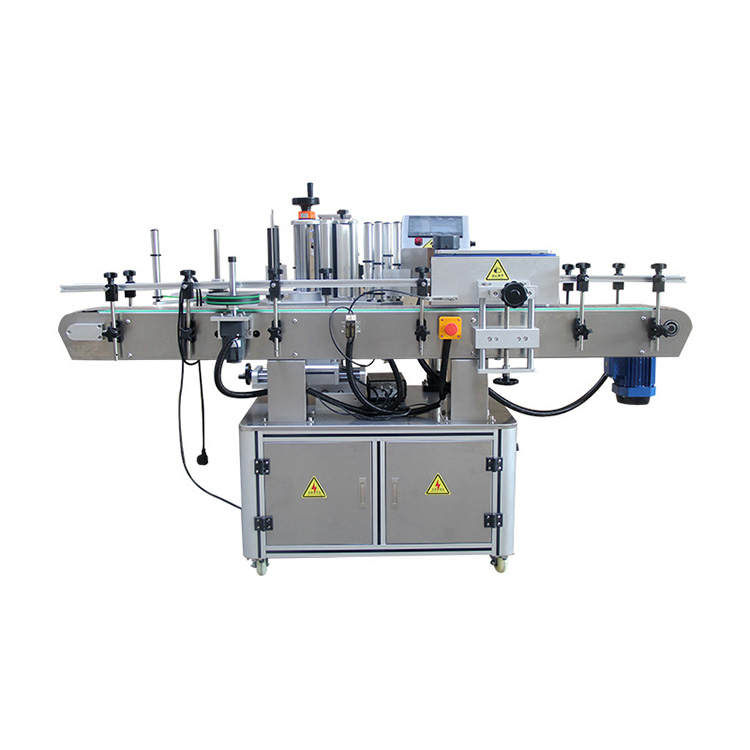

- Step 2: Caps Capping Once the cap was placed in the correct position. Such as the top of the bottle, jar, or jug. The capping head will execute the capping process because different caps may require different capping machines and capping methods. Then the capped container will be sent out by conveyor belt to the aluminum foil sealing machine or labeling machine. Then, the capping process is completed, and as same cycle.

How Does Spindle Capping Machine Work?

First of all, the working principle of the spindle capping machine is the spindle capper receives containers with caps already set in place and afterward immediately tightens the caps using three or four sets of matched spinning disks or spindle wheels. The capping process will certainly run continuously without bottles stopping for indexing, cap positioning, or any various other factors.

Usually, the spindle capping machine is matched with a cap elevator feeder or a vibrating bowl feeder to load the cap to obtain higher automation or higher capping speed. However, if you have a lot of kinds of caps, or the caps are not easy to feed, manually placing the caps is also a good choice.

Why Use Capping Machine?

- 1. Capping machines not only speed up the process of finishing packaging of your product, but they also ensure that each cap is sanitary and that the product does not get contaminated by handling.

- 2. Additionally, they allow you to save yourself from the repetitive motions of placing and tightening caps to each container yourself. There are a number of different capping machines that can help you package more product in less time—and not just the machines that place the caps on, either.

Things to Consider When Buying a Capping Machine

It is much more challenging to buying a capping machine perfect for your business from the existing market due to the many models and styles to dazzle you.

To help you make the right decision, VTOPS has analyzed several factors to help you in your search. Please click here to visit more.

Anyway, a capping machine will be beneficial to your production and business. At Zhengzhou Vtops Machinery Co Ltd, we specialize in large-scale production and customization of packaging machines, not limited to capping machines, so do not hesitate to contact us if you need.