Viscosity Liquid Piston Filler Machine Manufacturer

A piston fillers is a type of liquid filling machine used in various industries for filling containers, such as bottles, jars, and cans with liquids or semi-liquids. The machine works by using a piston to draw a specific amount of product from a storage tank and then depositing it into the container.

The piston filling machine is a versatile machine that can handle a wide range of liquids, including oils, creams, syrups, and more. It is commonly used in the food and beverage, cosmetics, and pharmaceutical industries.

Inline Piston Fillers

An Inline Piston Filler utilizes a conveyor belt to move containers in a straight line under the filling heads. Each head contains a piston-cylinder mechanism: the piston retracts to draw product into the cylinder from a bulk supply, then pushes it out into the container. This design offers precise control over product volume, making it suitable for various industries such as food, beverages, pharmaceuticals, and cosmetics. Its adaptability for different container sizes enhances its versatility.

Rotary Piston Fillers

A Rotary Piston Filler is an industrial filling machinecan fill a large number of containers quickly, used to dispense precise volumes of liquid or semi-liquid products into containers. Unlike inline fillers where containers move linearly, in rotary fillers, containers follow a circular or rotary path. As each container rotates under the filling heads, a piston draws product from a supply and dispenses it into the container. This process ensures high speed and accuracy, making it suitable for large-scale operations in industries such as food and beverage, pharmaceuticals, and cosmetics. The machine’s design also allows for continuous, high-speed filling operations.

Volumetric Piston Fillers

A Volumetric Piston Filler is a machine designed to dispense a precise volume of product into containers. The filler to administer a specific, pre-set volume of liquid or semi-liquid product into containers. It utilizes a piston-cylinder system where the piston’s movement determines the volume of product drawn into the cylinder from a bulk supply. The exact volume is determined by the distance the piston retracts, which can be adjusted as needed. This volume is then accurately dispensed into each container. This precision and adjustable volume settings make the Volumetric Piston Filler ideal for industries such as food, beverages, pharmaceuticals, and cosmetics, where accurate, consistent volumes are required.

Net Weight Piston Fillers

A Net Weight Piston Filler is an industrial fill-by-weight machine that fills a precise weight of product into each container. Unlike volumetric fillers, which measure volume, this machine uses weight as the main parameter. It operates using a piston-cylinder mechanism, drawing product from a supply and dispensing it into containers. The weight of the dispensed product is continuously monitored to ensure it meets the desired weight. This machine is ideal for industries where products are sold by weight, ensuring accurate, consistent product weight.

Thick Paste Piston Fillers

A Thick Paste Piston Filler is a specialized machine that fills thick or viscous products into containers. It handles products like salsas, relishes, creams, and sauces using a piston-cylinder mechanism. The advantages include the ability to manage high-viscosity products or those with solid pieces, accuracy in dispensing precise volumes, and adaptability to different container sizes. This machine is beneficial for industries like food processing, cosmetics, and pharmaceuticals that require flexible, precise, and efficient filling of diverse product types.

Servo Driven Piston Fillers

A Servo Driven Piston Filler uses a servo motor to control the movement of the piston filling, providing high-precision filling of liquids or semi-liquids into containers. The servo mechanism allows more accurate control over the piston’s movement than traditional mechanical and pneumatic systems. Advantages include superior precision and repeatability, smoother operation, and better adaptability to different product viscosities and container sizes.

Video

People Also Ask

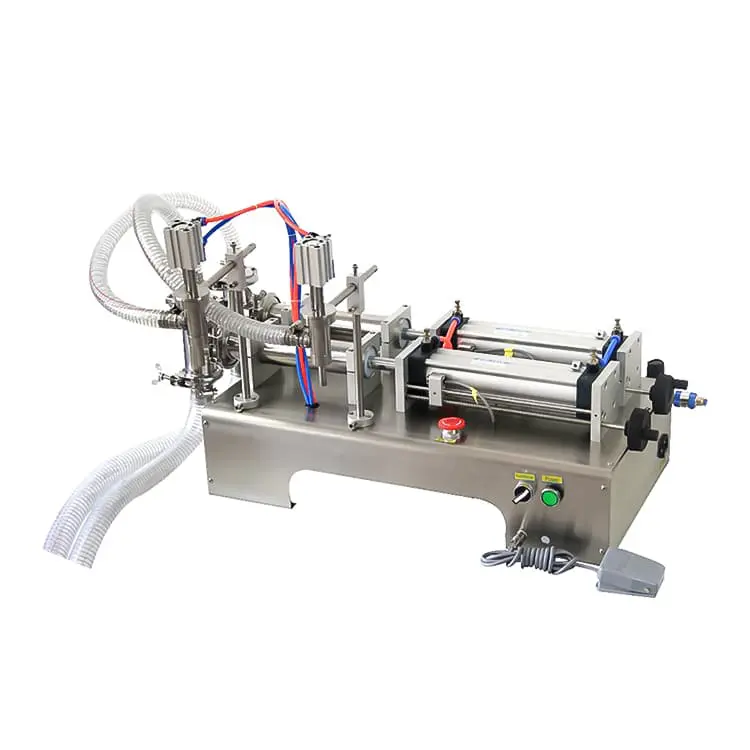

The Piston Filler has two driving modes: A compressed Air Drive and an Electric (Servo) Motor drive. The main difference between them is the following:

A Pneumatic Piston Filling Machine uses compressed air as its power source to drive the piston, which moves up and down to draw and dispense the liquid. This type of machine is suitable for filling products with low to medium viscosity liquid and does not require high filling speeds. Pneumatic piston filler machines are generally smaller, simpler, and easier to maintain compared to electric machines. However, the pneumatic drive type requires a huge amount of compressed air, which increases exponentially with the number of piston nozzles.

On the other hand, an Electric (Servo) Motor Piston Filling machine uses an electric motor to drive the piston. This type of machine is suitable for filling products with high-viscosity liquid or grainy sauce and requires high filling speeds. Electric Servo Piston Filler Machines are generally larger and more complex compared to pneumatic machines, but they offer greater versatility in terms of filling speed, accuracy, and control.

Overall, the choice between a pneumatic and electric piston filling machine depends on the specific requirements of the application, including the type of product being filled, the required filling speed and accuracy, and the available power sources. For VTOPS, we advice buying piston filling machines driven by servo motors, which have more quality assurance and precision.

Both Inline Piston Fillers and Rotary Piston Fillers are used to fill containers with precise product volumes. Here some key differences are the following:

- Movement: Inline Piston Fillers move containers in a straight line under the filling heads, while Rotary Piston Fillers have containers follow a circular or rotary path.

- Space: Inline fillers can be more compact and may be a better fit in production lines with limited space, whereas rotary fillers, often used for higher-speed, larger-scale operations, may require more space.

- Speed: Rotary fillers can generally fill more containers per minute than inline fillers, making them more suitable for high-volume operations.

- Flexibility: Inline fillers can be easier to change over for different container sizes. This makes them more versatile if your operation involves various container types.

- Complexity: Rotary fillers can be more complex in design, which can impact maintenance and the cost of operation.

- Cost: Inline Piston Fillers are typically less expensive, and Rotary Piston Fillers with more costly and maintenance costs.

Ultimately, choosing between an Inline Piston Filler and a Rotary Piston Filler depends on your specific operational needs, including production volume, space constraints, and the types of containers and products you are working with.

- Volumetric Piston Fillers: These machines fill a Specific Volume of product into each container, regardless of the product’s weight. This is ideal for products where the volume is more important than the weight, or where the product density is consistent.

- Net Weight Piston Fillers: These machines fill a Precise Weight of product into each container. This is essential for products that need to be sold by weight. They can compensate for minor variations in product density, ensuring that each container has the same weight of product.