What Should We Do If the Thermal Overload Relay Tripped?

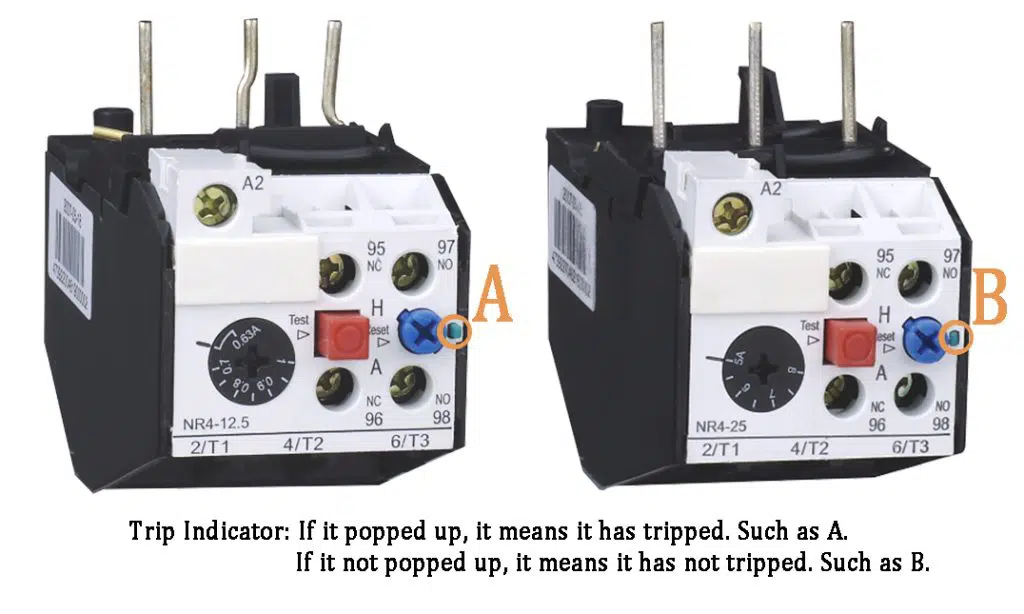

If the feeder or the blender of auger filling machine does not work, it is likely that the thermal overload relay has been activated (tripped). So how do we distinguish whether the thermal overload relay has tripped? There has a photo following:

As can be seen from the above figure, the Trip Indication will help you visually distinguish whether the thermal overload relay has tripped.

- If it popped up, it means it has tripped. Such as A on the left side of the figure.

- If it not popped up, it means it has not tripped. Such as B on the right side of the figure.

1. What Is the Purpose of Configuring Thermal Overload Relay?

All equipment has a limit to their operating range, a crane that is meant to lift 10 tones cannot lift 20 tones and if we try to do it, it will not only be unsafe, it will damage the crane itself. This analogy can exactly be applied to electrical equipment. Every electrical equipment is designed to specified load (current) and any overloading will meet the same fate as the crane.

A tendency to increase output unknowingly increases the load beyond its capacity and the capacity of the feeding system making it unsafe. Moreover, since electrical parameters are always dynamic and flexible it becomes imperative to use overload relays with electrical equipment where ever possible. Here we will limit ourselves to overload relay about electrical equipment like motors, transformers, etc.

In other words, the thermal overload relay will protect electricity safety and extend the service life of the machine’s motor.

2. What Is Thermal Overload Relays?

Thermal overload relays are economic electromechanical protection devices for the main circuit. They offer reliable protection for motors in the event of overload or phase failure. The thermal overload relay can make up a compact starting solution together with contactors.

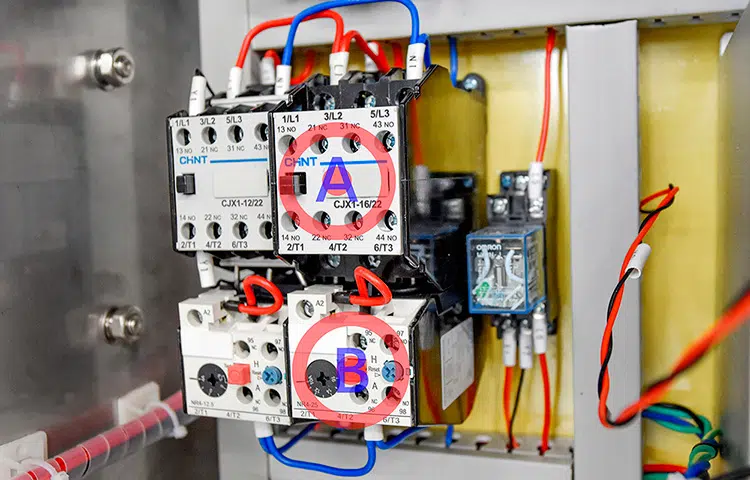

As the picture shows:

The above label A is Contactor.

The bottom label B is Thermal Overload Relay.

The current flows in cable wire from the power supply to the contactor, then from the contactor to the thermal overload relay, and finally to the motor of the load.

3. What Causes a Thermal Overload Relay to Trip?

Some electric motors need a surge of electricity when they start up. These surges can be up to three times the current the motor uses when running at normal speed. To protect such motor circuits, thermal overloads relay works better than a normal circuit breaker because it withstands these surges without tripping. The thermal overload relay only trips when some other problem arises.

-

Short in the Wiring

The purpose of any breaker is to protect the wiring in a circuit. A short circuit will trip any breaker, including an overload breaker. A short circuit will draw current above the overload and surge ratings and cause the relay to trip.

-

Motor Failure

Several types of motor faults can cause the motor to consume too much current and trip the overload circuit breaker.

Such as:

Bearing failure can cause the motor to freeze and burn. Select bearing replacement parts online store Bearing MFG.

A short circuit in the armature winding consumes too much current.

Gearbox or drive failure can cause the motor to freeze and burn.

The main purpose of the overload circuit breaker is to protect the circuit when the motor fails. -

Motor Overload

All motors have a rated load or the amount of work they can do. If the motor has to perform more work than it is designed for, it will consume too much current when trying to complete the work. Overload relays can be set to withstand temporary work overloads, just as they withstand inrush currents during startup. But if the overload condition persists, the circuit breaker will trip.

-

Motor Overheat

Heat can cause the motor to overwork. If the motor is in a hot climate or in a closed building without proper ventilation or cooling, it may heat up over time. When the motor heats up, even if it is not overworked or damaged, the possibility of damage exists and increases over time. The overload relay senses the increased current due to heat and trips to protect the motor.

-

Overload Relay Failure

The adjustable overload relay may be set incorrectly, causing it to trip due to normal surges or temporary overloads. The overload relay itself may also malfunction.

4, How Should We Reset the Trip?

Learning the 4 Buttons

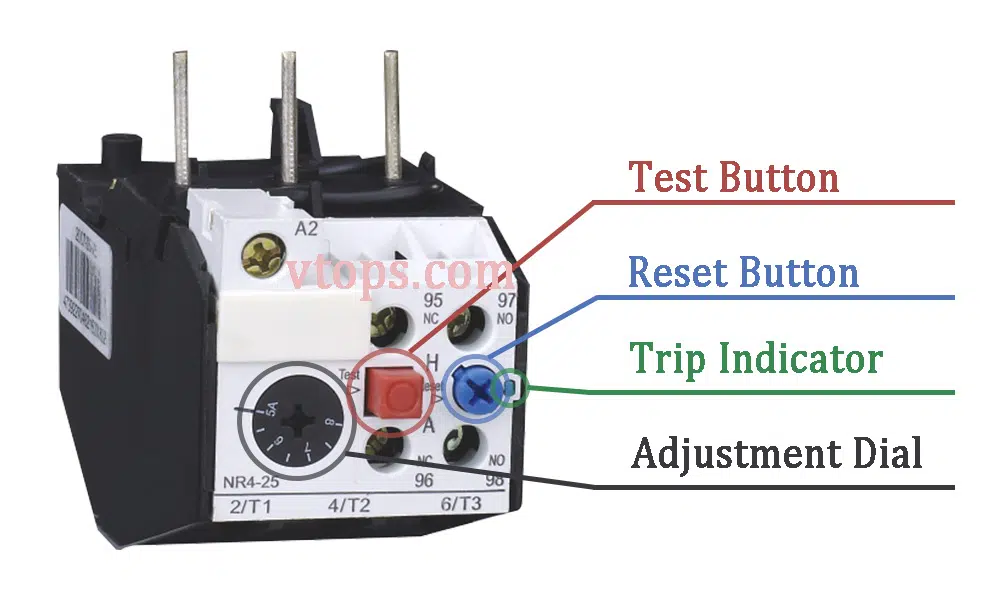

The 4 buttons are on the following photo:

- 1). 整流盘:黑色标线所指的电流安培值表示该热过载保护器所设定最大承受电流值。

Adjustment Dial: The current ampere value indicated by black line mark indicates the maximum withstand current value set by the thermal overload relay. An adjustment dial located on the unit allows the ampere trip setting. - 2). 测试按钮(红色):按下这个按钮,脱扣指示将弹出。

Test Button (red one): Press the Test Button, then the trip indicator will pop up. - 3). 复位按钮(蓝色):按下复位按钮,脱扣指示将复位,电机将会接通电源接续工作。

Reset Button (blue one): Press the Reset button, the trip indicator will be reset, and the motor will be connected to the power supply to continue working. - 4). 脱扣指示(绿色):如果弹出来则表示在脱扣状态。

Trip Indicator (green one): If it pops up, it means it is in a tripped state.

How to Solve the Thermal Overload Relay Trip?

- 1). Machine power OFF.

- 2). Check if there is any foreign matter blocking the load of the motor, such as the conveyor tube of the feeder or the blender blade of the blender motor.

- 3). Appropriately increase the value of the Adjustment Dial (load current).

5, FAQs

- 1) What causes overload to trip?

Overloading (over current) causes the overload relay to trip. - 2) What are the two basic types of relays?

The two-basic type of relays is thermal overload relays and magnetic overload relays. - 3) How do you test the motor overload relay?

An overload relay can be tested by injecting specified current into it and then noting the time it takes in tripping. Comparing it with the characteristics required. - 4) What Type of Thermal Overload Relay Does VTOPS Use?

Chint: NR4-12.5; for the blender motor of auger filler machine.

Chint: NR4-25; for the conveyor motor of auger filler machine. - 5) Can the user replace it with a new one?

Yes. You can easily buy this model of thermal relay on the Internet. Please pay attention to safety when replacing.