VTOPS is a company specializing in the production of filling machines, packaging machines, labeling machines, and other packaging machinery. Their products are popular around the world and are known for their high level of innovation and superior performance. The servo pump viscous piston filling machine produced by VTOPS has made a profound impact on New Zealand honey producers. Honey is representative of viscous liquids, and traditional filling methods may face various challenges when handling this special liquid. VTOPS’s piston filling machine offers a new solution for New Zealand honey producers. It successfully overcomes these challenges through its advanced technology and sophisticated controls. The introduction of this technology not only improves production efficiency and product quality but also helps reduce production costs.

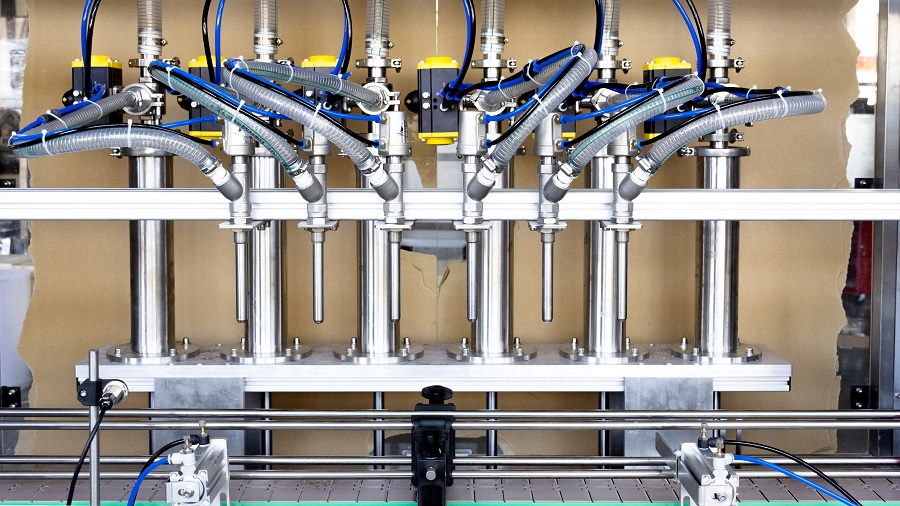

VTOPS Exported to New Zealand 4 Nozzle Servo Pump Viscous Liquid Piston Filling Machine

Mr. Chen is a natural honey supplier in New Zealand. His business has grown rapidly due to the expansion of production scale. In order to meet the growing market demand, Mr. Chen urgently needs to purchase an efficient honey filling machine. While searching for the right equipment, he discovered VTOPS, a reliable manufacturer of packaging and filling machines. As one of the top three packaging machine manufacturers in China, VTOPS has advanced technology and strong strength.

On May 18, Ms. Tina, a salesperson at VTOPS, received an inquiry from Mr. Chen about a honey filling machine on Alibaba. Mr. Chen put forward some requirements for the honey filling machine he wanted.

Filling Requirements

Filling Material: honey

Filling Capacity: 50ml-500ml

Bottle Height: 63mm-120.4mm

Bottle Mouth Inner Diameter: 45mm-73.5mm

Number of Machine Nozzles: 4 nozzles

Ms. Tina analyzed Mr. Chen’s needs in detail and suggested to him that a servo pump viscous liquid piston filling machine is the best choice for filling honey. Honey is a very viscous liquid, and its viscosity is determined by its glucose content. Honey is relatively slow to flow and process, requiring appropriate equipment to ensure a smooth production process.

The piston filling machine is specialized in handling viscous liquids. Through precise piston movement, it can efficiently and accurately fill viscous liquids, such as honey, sauces, liquid spices, etc., into containers. Due to their high adaptability, piston filling machines are widely used in industries such as food, pharmaceutical, and cosmetics industries. Whether it is small-scale production or large-scale industrial production, piston fillers provide key solutions for the production of viscous liquids.

Reach Cooperation

After Ms. Tina made suggestions, she provided Mr. Chen with relevant videos of the piston filling machine. The videos demonstrate the outstanding performance of this efficient and precise device in action, particularly in handling viscous liquids. After watching the video, Mr. Chen discussed it with his professional technical team and decided to cooperate with VTOPS after discussion.

Mr. Chen paid for the machine on June 16. He was very grateful to Ms. Tina for her professional advice. Mr. Chen said that the price of VTOPS machines is more competitive than other manufacturers. This is critical to his business, as cost control is an important consideration while scaling up production.

On July 14, VTOPS completed the production of piston filling machines. Ms. Tina took detailed photos of the machine for Mr. Chen so that Mr. Chen could carefully check the status and configuration of the equipment. After careful inspection, Mr. Chen spoke highly of VTOPS’s process and manufacturing capabilities. In order to ensure the safety of the equipment during transportation, VTOPS arranged wooden box packaging to protect the machine. After Mr. Chen received the machine, VTOPS further provided online operation guidance. Through online operation guidance, Mr. Chen can obtain professional technical support to solve any operational problems or concerns.

Things to Note When Filling Honey With Piston Filling Machine

1. Cleaning and Disinfection: Before starting filling, ensure that the piston filling machine is in a clean and sanitary condition. All parts of the equipment, especially those that come into contact with honey, should be cleaned and disinfected regularly.

2. Honey Temperature Control: The viscosity of honey will change with temperature changes. Make sure the honey is at the right temperature, usually between 30-40°C, to make it easier to handle and fill.

3. Accurate Volume Control: Adjust equipment to ensure accurate volume control to avoid over- or under-filling.

4. Maintain Equipment: Regularly inspect and maintain the piston filling machine, including seals, pistons, valves, etc., to ensure normal operation of the equipment.

5. Prepare Appropriate Containers: Use appropriate containers to store honey, ensuring they are clean, dry, and properly sterilized before filling.

6. Hygiene Standards: Comply with hygiene standards and regulations and ensure operators use appropriate protective equipment, such as gloves, to ensure the hygienic safety of honey.

As a new type of high-end machinery, the automatic servo piston filling machine has excellent automation capabilities. It can not only operate independently but also work closely with other automated equipment, such as bottle unscramblers, automatic capping machines, automatic labeling machines, etc., to form a highly integrated production line. VTOPS focuses on the individualization of customer needs and can customize the most suitable packaging solutions for customers. Whether it is liquid, powder, or viscous liquid, VTOPS’ professional team can customize it according to the customer’s specific needs. No matter what industry you are in, VTOPS is committed to helping you achieve efficient, innovative packaging that makes your products stand out.