Nuts Packaging and Detection Equipment Ensure Nuts Food Safety

Recently, the Chinese snack food brand “Three Squirrels” released its semi-annual report. The data shows that in 2022, the company’s operating income was 72.93 billion yuan, achieving a single-day sales record of over 200 million yuan. The market size of roasted seeds and nuts is second only to candy, chocolate and candied fruit. The expansion of the nut market is inseparable from the quotation escort of the nuts packaging and detection equipment.

Among them, the revenue of the nut category reached 21.95 billion yuan, an increase of 9.59% year-on-year. According to a survey, 61% of Chinese consumers recognize the high nutritional value of nuts.According to statistics from the China Food Industry Association, in 2021, the annual output value of my country’s roasted nuts industry will reach 151.2 billion yuan. The scale ranks second among all kinds of snack foods.

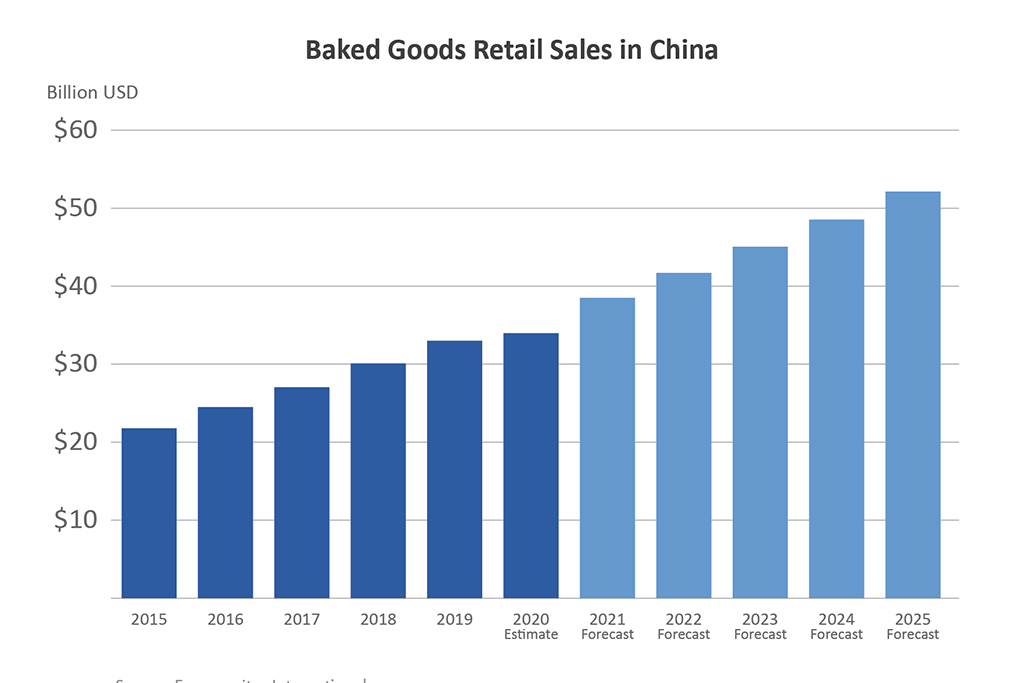

China’s Total Nut Imports

Nuts, rich in protein, dietary fiber, and unsaturated fatty acids, are gradually becoming more popular as healthy food. The global nut industry continues to grow, covering multiple aspects such as planting, processing, packaging, transportation, and sales.

However, China’s nut industry is different from other industries. Most of the raw materials rely on imports. Among the imported nuts, pistachios are the largest category, ranking first in both import value and import volume. The total import value increased by more than 500 million US dollars from 2016 to 2020. In recent years, macadamia imports have increased from 8,442.8 tonnes to 20,100 tonnes. Import volume increased by 1261%, an increase of 138.20%.

Factors to Consider in Nut Packaging

With such a large volume of imports, packaging plays an important role. Use professional nuts packaging and detection equipment. Strictly control nut safety issues during the packaging process. Three Squirrels, Bestore, Wolong, Baicaowei, etc. are the leading companies in China’s nut market. Especially for similar well-known nut manufacturers, it is necessary to choose suitable nut packaging and detection equipment. Enterprises need to comprehensively consider factors such as nut characteristics, packaging materials, cost budget, and equipment durability. This helps nut manufacturers realize automated production and improve product production efficiency. At the same time, the freshness and nutritional value of nuts are protected, and the added value and market competitiveness of the product are increased.

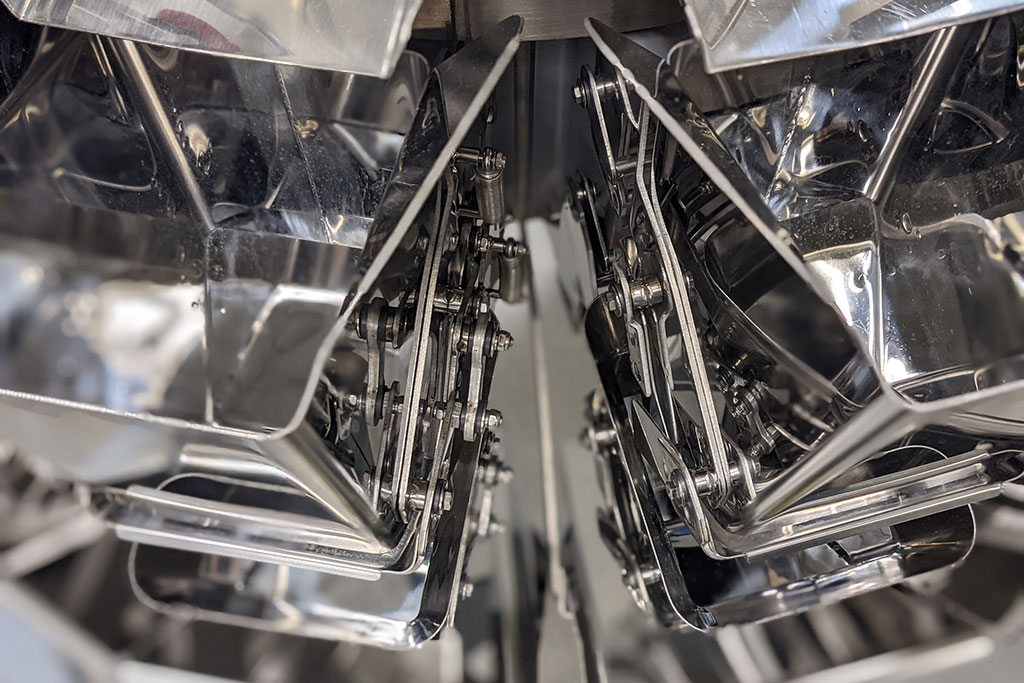

High-Precision Multi-Head Scales

High-precision multi-head scales are particularly important for the weighing segment in nut packaging processes. Multi-head scales can quickly and accurately weigh nuts, ensuring that the weight of each package complies with regulations. Multi-head scales are typically combined with filling machines, sealing machines, and other packaging equipment to automate the weighing, filling, and sealing of nuts.

- High Accuracy: Multi-head scales can accurately measure the weight of nuts in each hopper and use combination calculations to achieve results that are closest to the target nut packaging weight.

- Fast Speed: Due to multiple weighing heads working simultaneously, high-precision multi-head scales can quickly complete weighing tasks, making them suitable for high-volume nut production lines.

- Labor-saving: Multi-head scales, usually integrated with automated packaging lines, can automate the weighing, packaging, and sealing of nuts, reducing human intervention.

Nuts Packaging and Detection Equipment—Metal Detectors

In addition to choosing a quality multi-head scales, metal detectors are also important when it comes to packing nuts. If the equipment is used for too long, problems such as wear and tear will occur. Metal contamination may occur during nut production and processing. Metal detectors can effectively detect and reject products containing metal contaminants. Thereby ensuring the safety and quality of nuts.

- Protect Consumer Health: The use of metal detectors helps prevent metal contaminants in nuts from entering consumers’ bodies, ensuring food safety and protecting consumer health.

- Protect Brand Image: By using metal detectors, nut manufacturers can promptly identify and address problematic products, avoiding damage to their brand image and reputation due to metal contamination incidents.

- Prevent Economic Losses: Metal detectors can detect metal contaminants in the early stages of nut packaging, avoiding the need for a recall of an entire batch of products and reducing economic losses.

Nuts Packaging and Detection Equipment—Checkweigher Machine

Checkweigher machine play an important role in the packaging production of nut products. On the one hand, it helps to improve the production efficiency of nuts. On the other hand, it helps nut manufacturers meet regulatory requirements.

- Ensure Nut Packaging Consistency: Checkweigher machine ensure that the weight of nut products in the package matches the weight indicated on the label. This ensures consumers receive the quantity they purchased and avoids waste due to overfilling.

- Improve Nut Production Efficiency: Automatic checkweighers are more efficient and accurate than manual methods. This helps keep the nut production line running continuously and reduces production costs.

- Reduce Nut Packaging Waste: By ensuring that the weight of each nut package meets the requirements, checkweighers help reduce waste and avoid product weights that are above or below the standard.

- Compliance of Nut Brands: Many countries’ regulations require food and beverage companies to ensure that product weights correspond to descriptions on labels. Automatic checkweighers help companies comply with these regulations.

Nut Packaging and Detection Equipment Technology and Trends

With the rapid growth of China’s nut market, nut packaging technology is developing in the direction of intelligence, automation and sustainability.

- Smart packaging: Using RFID, QR code, and Bluetooth technology, smart packaging can provide consumers with more product information. For example, using RFID labeling machines to label nut products, nut manufacturers can use RFID tags for logistics tracking. More efficient inventory management and asset tracking are also possible.

- Active Packaging: Adding substances with antioxidant and antibacterial functions, active packaging can extend the shelf life of food and reduce the risk of nut oxidation and microbial contamination. For example, nut manufacturers need to vacuum pack nut products. Then the vacuum packaging machine can be used to extract the air in the package to establish a vacuum environment. Secondly, during the operation of the sealing machine, active packaging materials (such as packets containing desiccant) can be sealed together in the package.

- Sustainable Packaging: With the increasing awareness of environmental protection, sustainable packaging has become a trend. Biodegradable materials, paper packaging and minimal packaging are sustainable packaging options. It can reduce the impact on the environment and meet consumer demand for environmentally friendly products. For example, when using a nut sealer, you can choose sustainable sealing materials such as recycled plastic film. When using the nut filling machine, nuts can be filled into recyclable or reusable containers, such as glass bottles, aluminum cans, etc.

Conclusion

The Chinese nut market is growing rapidly, with a market size close to 50 billion yuan. However, compared to foreign countries, China’s per capita consumption of nuts is still low. It is estimated that the per capita nut consumption in China is only 3.2% of that in the United States. The nut consumption market has huge development prospects. To this end, China’s nut manufacturers still need to use high-quality nut packaging and testing equipment to improve product quality and meet consumer demand.