Vacuum refers to a state in which the gas pressure in a certain area is far lower than the atmospheric pressure. The density of gas molecules is very thin and close to non-existence. It is relative to atmospheric pressure, so the vacuum level is usually defined in terms of the pressure level of a gas.

Vacuum Application Range

Vacuum has a wide range of applications covering many different areas. A vacuum is a good way to manufacture and process materials in industry. In scientific research, a vacuum provides a controlled environment for studying the properties and interactions of matter. Medical equipment, radiotherapy, and pharmaceutical production need a vacuum in the medical field. In addition, vacuum plays a key role in space exploration, food processing, packaging, transportation, and environmental engineering. The wide range of applications highlights the versatility of vacuum technology. It provides critical support and solutions in different industries, thus promoting technology’s continuous innovation and development.

What Is a Vacuum Conveyor Feeder?

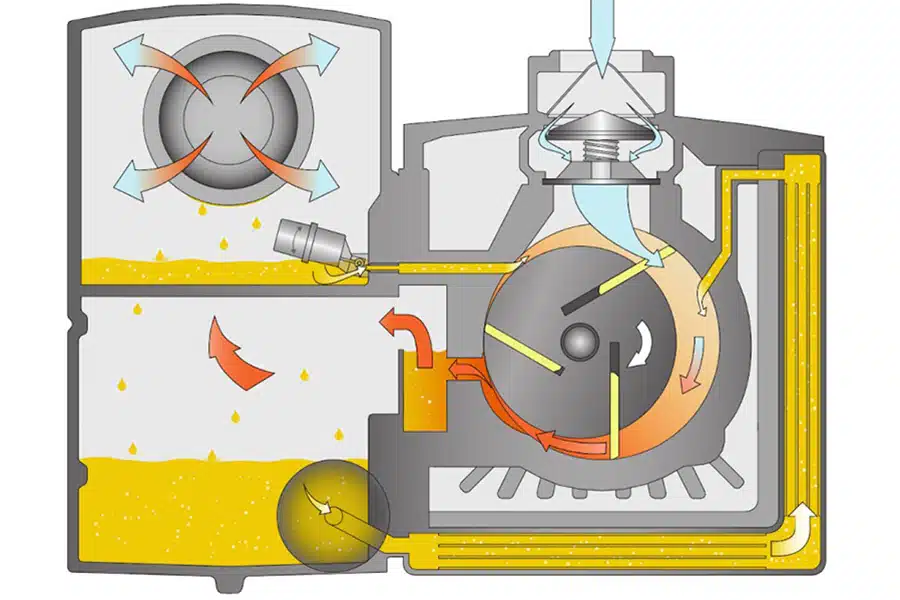

Image Description: Schematic Diagram of Vacuum Conveyor Feeder.

Image Description: Schematic Diagram of Vacuum Conveyor Feeder. Advantages of Vacuum Conveyor Feeders Compared To Screw Conveyor Feeders

- Vacuum conveying systems usually have precise material control and flow control functions. It can achieve highly accurate material delivery and mixing ratio control.

- Due to its working principle, vacuum conveying can reduce oxygen contact during the conveying process, thereby helping to prevent oxidation and contamination of materials. This is very important for applications with high requirements for material purity.

- Vacuum conveying can reduce dust generation, help maintain a clean working environment, and reduce the impact on workers’ health.

- The vacuum conveying system is beneficial for long-distance material transportation without requiring a large number of support structures and equipment.

The Use of Vacuum Conveyor Feeders in the Food Packaging and Filling Industry

In the food filling and packaging industry, the vacuum feeder is vital to transport food ingredients from one location to another. The following are the applications and advantages of vacuum conveying feeders in the food filling and packaging industry:

Application:

- Powdered Raw Material Transportation: In food production, it is often necessary to transport powdered raw materials from storage containers or warehouses to other machines. Vacuum conveyor feeders accomplish this task efficiently and accurately.

- Conveying Granular and Block Materials: During the food packaging process, manufacturers must transport some granular or block materials (such as grains, nuts, raisins, etc.) to the feeding port of the packaging machine. Vacuum conveyor feeders can handle these different types of materials with ease.

- Prevent Oxidation: In food processing, some raw materials or finished products are sensitive to oxygen. Therefore, it is necessary to reduce oxygen contact during transportation to prevent oxidation. Vacuum conveying systems are very useful in this regard.

Advantages:

- Food Quality and Safety: A vacuum conveyor feeder helps maintain food quality and safety by reducing oxidation and contamination of materials.

- Precise Control: This system allows precise control of the conveying speed and quantity of materials, ensuring the consistency of food products in each batch.

- Efficient Production: The vacuum conveying system can improve production efficiency, reduce manual operations and material waste, and reduce production costs.

- Cleaning and Hygiene: These systems are generally easy to clean, maintain, and meet food hygiene standards.

- Flexibility: The vacuum conveyor feeder is suitable for different types of food, and the parameters and configuration can be adjusted as needed.

Supporting Mechanical Equipment for Vacuum Conveyor Feeders

- Packaging Machine: Vacuum conveyor feeders can cooperate with various packaging machinery and equipment, such as automatic filling machines, sealing machines, label attachment machines, etc., to realize the packaging of food, medicine, and other bulk products.

- Mixers: In the food and chemical industries, vacuum conveyor systems can conjunction with mixers to ensure even mixing of raw materials and produce consistent mixtures.

- Storage and Material Storage System: Vacuum conveyor feeders can link with storage equipment and material storage systems to manage raw materials storage, replenishment, and automatic supply.

- Conveyor Belt System: In conjunction with a conveyor belt system, it enables long-distance material transportation and is typically employed in logistics and warehousing.

- Drying Equipment: In the pharmaceutical and food industries, vacuum conveying systems can make conjunctions with drying equipment, such as ovens or drying chambers, to transport materials and control humidity during the drying process.

- Crushing and Grinding Machines: In the pharmaceutical, chemical, and food processing fields, vacuum conveying systems can transport raw materials into crushing or grinding machines to achieve the production of powders or granules.

- Packaging Inspection Equipment: Vacuum conveyor feeders can be used with packaging inspection equipment to ensure packaging quality and integrity, which is especially important in the food and pharmaceutical industries.

- Material Grading and Sorting Equipment: In the agriculture, mining, and construction materials industries, vacuum conveying systems can be used with material grading and sorting equipment to classify and separate raw materials.

Conclusion

The vacuum conveyor feeder can be used with many different types of mechanical equipment and industrial systems as a multi-functional equipment. Used with supporting machinery to meet material conveying and handling needs in different industries and applications. At the same time, it can also improve production efficiency, ensure product quality, and automate the production process.