Zhengzhou Vtops Machinery Co Ltd, founded in 2001, is one of the top 3 powder filling machine manufacturers in China. Since its establishment, VTOPS has been adhering to the concepts of innovation and quality and has continued to grow and develop. We focus on providing highly customized and diverse powder filling solutions to global customers. On August 6, 2019, Mr. Ahmed from Somalia placed an order with VTOPS and hoped that VTOPS would contact its agent to deliver the goods. VTOPS then contacted Mr. Ahmed’s agent, Mr. Haji, and reached an agreement to inspect VTOPS for semi-automatic auger filler on August 10. On August 10, Mr. Haji arrived at the VTOPS factory on time for inspection, as agreed.

How Mr. Ahmed got in touch with VTOPS

Mr. Ahmed is the manager of a flour production and packaging company. According to production needs, he needs to order a semi-automatic auger filler to meet the growing production needs. Mr. Ahmed found VTOPS through Alibaba. After carefully reading the semi-automatic auger filler posted by VTOPS on Alibaba, he sent an inquiry.

After receiving the inquiry, sales of VTOPS learned about Mr. Ahmed’s detailed needs and recommended a suitable machine to him. During the exchange, Mr. Ahmed expressed high appreciation for VTOPS’s services. Mr. Ahmed arranged for his agent, Mr. Haji, to inspect VTOPS’s machines to ensure that the machines could meet his requirements.

Machines under Inspection

Semi-automatic auger filler VTOPS-P2 is a packaging equipment for powder or granular materials. It takes products from storage bins or containers through an auger conveyor system and accurately fills them into packaging containers. With a certain degree of automation, it can improve packaging efficiency and reduce manual operations.

It has high-precision filling and can adapt to packaging needs of different capacities. The operation is relatively simple, reducing human errors and improving production efficiency. At the same time, the semi-automatic auger filler has a compact structure and is suitable for packaging various granular and powder products. Powder fillers are widely used in food, pharmaceutical, chemical, and other industries.

2. Screw Conveyor Feeder | VTOPS-F114S

The screw conveyor feeder VTOPS-F114S is a device for material transportation. It transports materials from one location to another via a rotating screw. People often use this kind of equipment to transport powder and granular materials. It has the characteristics of high flexibility, wide adaptability, and small floor space.

Screw conveyor feeders enable efficient material transport. It adapts to different material types and conveying distances operates stably, and makes less noise. Screw conveyor feeders can also be used in different industrial fields, such as food processing, agriculture, chemicals, construction materials, etc. It effectively improves production efficiency and reduces labor costs. It is one of the most important conveying equipment.

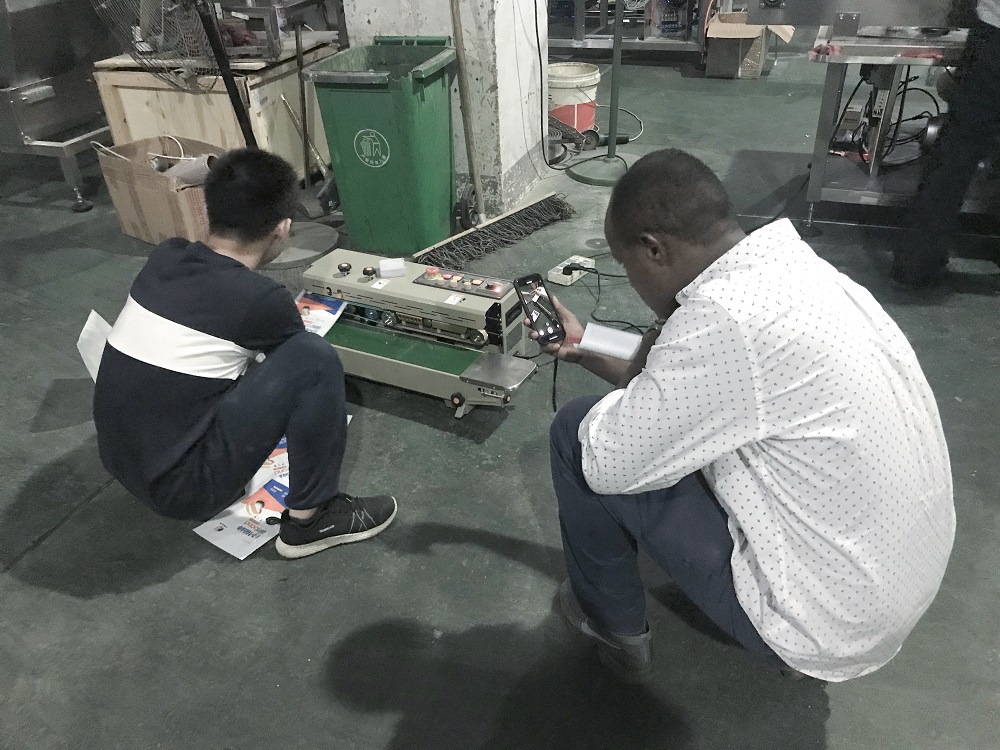

3. Continuous Band Sealer Sealing Machine | FRD-1000-2

A continuous band sealer sealing machine FRD-1000-2 is a packaging sealing equipment to seal various types of packaging bags or packaging films. It heats and seals the packaging material through a continuous sealing tape to form a sealed package. This machine is suitable for the packaging needs of food, pharmaceutical, chemical, electronics, and other industries.

A continuous band sealer sealing machine ensures high efficiency and consistent sealing quality. It is suitable for different types and sizes of packaging bags, improving packaging speed and production efficiency. The continuous band sealer sealing machine also has the characteristics of firm sealing, good sealing performance, and beautiful appearance. This helps to extend the shelf life of the product and maintain the freshness of the product. In addition, it can be integrated into automated production lines. The complete production line reduces manual operations, reduces labor costs, and improves the efficiency of the packaging process.

Main Items of Inspect VTOPS

1. Visual Inspection:

Visual inspection is done by looking at the outside and inside of the equipment to assess the overall condition of the equipment. This includes checking the machine’s external appearance to ensure there is no damage, rust, loose parts, or powder leakage. Internal visual inspection involves opening the casing of the device. Check parts such as internal components, transmission systems, and electrical connections to make sure they are not abnormal or damaged.

2. Performance Check:

Performance checks involve testing various functional and performance parameters of the device to ensure that it is working properly. It mainly includes functions such as start, stop, speed control, and cycle operation of test equipment. The purpose is to ensure that all control systems are functioning properly. Performance checks also include testing the equipment’s throughput, i.e., whether it can fill powder at a predetermined rate and accuracy. It is also possible to test the equipment’s automated functions, such as automatic filling, metering, and packaging.

3. Accuracy Test:

Accuracy testing is a check on how accurately the equipment measures and packs the powder. This includes checking the equipment’s metering system to ensure it is capable of filling the powder at the intended dosage and capacity. Sampling inspection can also check whether the weight or volume of the filled powder products meets the specified standards. Accuracy testing typically involves the use of standards or engineering samples to verify the accuracy of the device and calibrate it as needed.

Results of Inspect VTOPS

According to Mr. Ahmed’s request, the powder filling weight is from 500g to 2000g, with two auger filling tubes. Set the filling weight to 500g on the touch screen of the machine, and then fill it into the bag. VTOPS-P2 requires three automatic calibrations before it can work normally. The filling test lasted 2 minutes, and the scale showed that the weight of each filling was 500g. The test result is 100% filling accuracy.

Inspections of the screw conveyor feeder showed that the equipment was operating normally. The screw has no abnormal wear or looseness, the electrical connection is firm, and the lubrication system works well. The test results are all normal, and the transmission speed is good.

At Mr. Ahmed’s request, the materials will be bagged. Therefore, the continuous band sealer sealing machine FRD-1000-2 was used for testing. After turning on the power, the machine is heated, and then the bag is placed in the seal and sealed. The test result is that the packaging is very tight.

After trying it out, Mr. Haji spoke highly of the machine. Mr. Haji reported the inspection contents to Mr. Ahmed and arranged for the financial staff to pay the payment. VTOPS received 100% of the payment and arranged packaging quickly.

Pleasant Dinner Time

After everything was over, it was time for dinner. Mr. Zhang from VTOPS warmly invited Mr. Haji to have dinner. They came to a Muslim restaurant because Mr. Haji is Muslim. Mr. Haji said that this cooperation is very pleasant. If there is still demand for purchases in the future, he will cooperate with VTOPS again. The reason is that after this inspection, he has trust in VTOPS company and product quality.