As a widely popular food, milk powder has become an indispensable part of people’s lives. Because of its super high nutritional value, it exists in the eating habits of people of all ages and lifestyles. In today’s fast-paced life, powdered milk has become one of the first choices for babies, students, professionals, and travellers. Therefore, maintaining the quality and freshness of milk powder is of great importance to the food industry and consumers. This is also the reason for the emergence of vacuum lock-fresh packaging technology.

Why Is Milk Powder Preservation So Important?

Milk powder preservation is very important because it is directly related to the health of consumers and the quality of products. Nutrients rich in milk powder, such as protein, vitamins, and minerals, are susceptible to oxidation, moisture, and microbial contamination. This will reduce the quality and taste of the product and lead to health problems such as food poisoning.

Adopting appropriate fresh-keeping measures can effectively extend the shelf life of milk powder. It ensures that consumers can obtain high-quality, fresh products when using them, meeting their food safety and nutrition needs. In addition, as a common food and an important food ingredient, milk powder preservation is also critical to the food supply chain and business success. Therefore, milk powder preservation is related to personal health and the food industry’s sustainable development and market competitiveness.

VTOPS Launches Vacuum Lock-fresh Packaging Technology

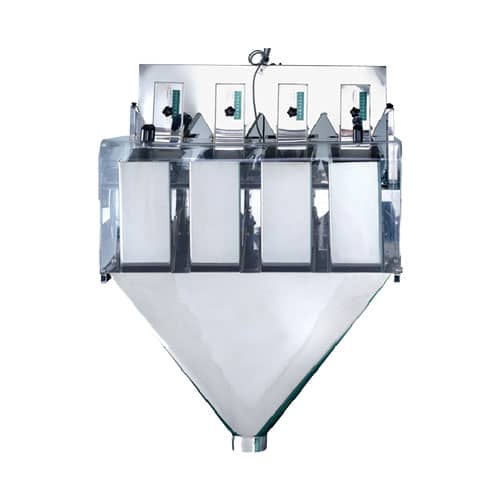

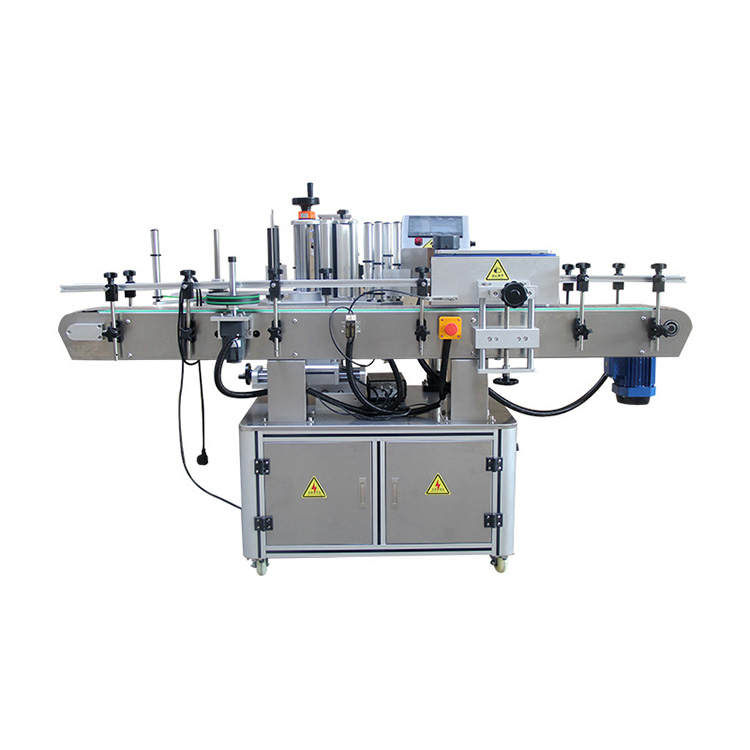

VTOPS is a company specializing in producing , which launched vacuum lock-fresh packaging technology in 2013. Vacuum lock-fresh packaging technology is a food packaging method that creates a vacuum environment. Extracting the air in the packaging container can reduce oxygen exposure and prevent microbial growth and food oxidation reactions. A vacuum environment can extend the shelf life of food and maintain its freshness and quality while maintaining the nutritional value of the food. This vacuum-sealed technology is widely used in the food industry, including the packaging of milk powder, meat, seafood, vegetables, fruits, etc., which helps improve food’s durability and freshness.

Challenges in Milk Powder Preservation

Milk powder preservation faces many challenges, including oxidation, moisture, microbial contamination, and storage conditions. First, the fat and protein in milk powder are susceptible to oxidation, decreasing product taste and nutritional value. Second, moisture can cause clumping and bacterial growth, compromising milk powder quality and food safety. Microorganisms such as bacteria and mould may also grow under inappropriate conditions and cause food to spoil. In addition, improper storage conditions, such as high temperature and humidity, may also accelerate the spoilage process of milk powder. Therefore, effective milk powder preservation methods and technologies are essential to overcome these challenges and ensure product quality and safety. The vacuum lock-fresh packaging technology which VTOPS launches can effectively solve the challenges of milk powder preservation.

Advantages of Milk Powder Vacuum Lock-Fresh Packaging Technology

Milk powder vacuum lock-fresh packaging technology has several significant advantages that make it an important choice for food packaging. Especially for some kinds of food, such as milk powder, are susceptible to oxidation and moisture:

- Extended Shelf Life: One of the most obvious advantages is significantly extending the milk powder’s shelf life. A vacuum environment can reduce the contact between food and oxygen, thereby reducing the speed of the oxidation reaction. It can prolong the freshness and quality of the milk powder and keep food edible for a longer time.

- Prevent Oxidation and Quality Loss: Vacuum lock-fresh packaging technology can prevent fat and other sensitive ingredients in milk powder from oxidation. This helps to maintain the formula’s texture, color, and flavor, making it more like a freshly made formula.

- Maintain Nutritional Value: Vacuum packaging helps to maintain the nutritional components in milk powder, such as protein, vitamins, and minerals. Reducing the degree of degradation due to oxidation allows the milk powder to retain its nutritional value during storage.

- Prevent the Entry of Moisture and Bacteria: In addition to reducing oxygen, vacuum fresh packaging can also prevent moisture and reduce the possibility of bacterial growth. This helps prevent the caking of powdered milk and maintains food hygiene and safety.

- Reduced Food Waste: Extending the shelf life of milk powder means less food wastage. If the product is easier to keep and use, consumers can get more out of the milk powder without worrying about premature food spoilage.

- Improve Market Competitiveness: Milk powder with high-quality packaging is more competitive, and consumers are more willing to buy products with long shelf life and good quality.

Detailed Steps of the Working Principle of Vacuum Preservation Technology

- Prepare the food: First, keep the food fresh in a special vacuum bag, container, or jar. These packages usually have good oxygen barrier properties to prevent outside air from entering the package.

- Air extraction: Use a vacuum sealer or packaging machine to extract the air in the packaging container. This step needs a vacuum pump or suction system to finish. The pumping air reduces the pressure inside the packaging container, causing the packaging material to fit tightly around the food.

- Sealing: Once the machine extracts the air, the packing machine will seal the packaging container to ensure that outside air cannot re-enter. People use heat sealing or other sealing techniques to finish the sealing.

- Freshness Preservation and Storage: In a vacuum environment, the oxygen and microorganisms are inactive, thereby reducing the speed of food oxidation and spoilage. This allows the food to retain its freshness and quality for longer. Proper temperature and humidity condition is essential for vacuum-packed foods to further extend the shelf life.

Conclusion

Vacuum lock-fresh packaging technology offers many benefits to manufacturers in the milk powder industry. For example, it can extend the shelf life of products and reduce inventory losses, product oxidation and moisture absorption. It effectively improves production efficiency, reduces packaging and transportation costs, and enhances product market competitiveness. Unique advantages bring greater profits and sustainable development opportunities to enterprises.

VTOPS always adheres to its commitment to providing excellent customer service and provides advanced vacuum lock-fresh packaging technology to all milk powder manufacturers. VTOPS provides advanced technical solutions and strives to establish close cooperative relationships. Gain a deep understanding of your client’s needs and goals to tailor the most appropriate solutions. VTOPS will do its best to meet the needs of each customer and help customers achieve greater success and sustainable growth.