China's Reliable Induction Sealer Machines Supplier

The induction sealer machines are non-contact devices used to seal the tops aluminum foil of containers such as bottles and jars. These machines have the capability of sealing a variety of containers using the induction method with the non-contact mechanism.

What Is An Induction Sealer Machine?

An induction sealer machine is a device that is used to seal the tops of containers such as bottles and jars. These machines can seal various containers using the induction method with the non-contact mechanism.

Induction sealing is the method of sealing thermoplastic materials together by heating them using an induction coil. Perhaps the most widely used application of induction sealing is cap locking. This process involves heating an inner seal without directly contacting the container’s surface.

Induction sealer machines are primarily used in the packaging industry. They provide induction sealing solutions for the pharmaceutical, agrochemical, healthcare, food, beverage, and petrochemical industries. An induction cap foil sealing machine ensures that the content is protected from harm or leakage by airtightness. The machine also ensures that the content is tamper resistance.

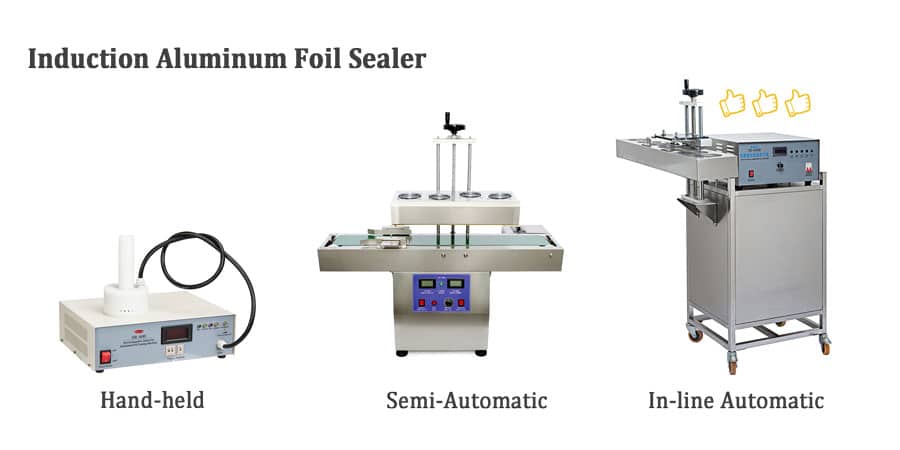

We are experienced in manufacturing high-quality and a wide variety of induction sealer machines. These machines include hand-held induction sealer machines, semi-automatic induction sealer machines, and heavy-duty inline automated induction sealer machines.

Our induction sealer machines may be tailor-made for enterprises or depending on your requirements. Induction sealers may be used on various containers, including glass and polythene bottles and jars.

Products of Induction Sealer Machine for Sale

An induction sealer machine provides an excellent sealing solution for any size container and may be adapted to meet the specific demands of the business. VTOPS provide customers with the following 3 high-quality electromagnetic induction aluminum foil sealing machines.

If you are interesting the induction sealer machine price, please submit a quickly inquiry of following:

Submit Your Request

Features of Induction Sealer Machine

- An induction sealing machine utilizes the electromagnetic induction concept. The machine is also simple to operate since it can be handled with one hand making it excellent for small-scale manufacturing.

- An induction sealing machine employs a hermetic sealing method that protects the content from leakage and contamination. Hence gives excellent tamper resistance for the packaging.

- An induction sealing machine has a sealing capacity that depends on the type of the machine. Manual induction sealer machine has a sealing speed of 4-6 bottles /minute while semi-automatic induction sealer machine has a capacity of 4-16 bottles/ minute. The automatic induction sealer machine has a sealing capacity of up to 25 bottles per minute.

- An induction sealer machine’s efficiency is boosted by the reduced waste and the preservation of the package’s visual appeal. The machine’s calibration and setup are simple and user-friendly, allowing for the administration of a variety of label sizes and kinds.

An induction sealer machine has internal counters and performance monitoring that identifies mistakes and defects and prevents additional harm from occurring. - The induction cap sealing machine comes with a wide range of optional components that add value to the system. As productive equipment, the induction sealer machine has characteristics that provide consistent output results based on the measurements taken.

How Does Works

An induction sealer machine employs non-contact hermetic sealing. The process starts when the induction sealer machine receives the capped bottles from the capping machine or manual capping. This process is achieved by passing a bottle beneath an induction sealer, which generates a hermetic seal. Induction sealing requires induction heating to join thermoplastic materials. It includes using electromagnetic induction to heat an electrically conducting material using eddy currents’ heat created in the item.

After running the capped or closured container through an induction coil, the induction coil creates a spinning electromagnetic current. Eddy currents allow the conductive foil liner to warm up as it passes over the sealing head. The wax is incorporated into the pulp covering to detach the foil from the cap. The polymer coating on the container’s rim heats up and flows over it. The polymer binds to the container throughout the cooling phase, resulting in a totally sealed package. A manual induction sealing machine or a conveyor system can be employed to securely seal the product. A hermetic seal is formed when heat and pressure are applied to the inner seal, causing it to adhere to the container’s lip and form a hermetic closure.

The bottle and contents are unharmed; unless the heat produced is excessive, it has no detrimental effect on them. Only if the foil is overheating is when the protective layer and seal layer may be at risk of damage. Even days since the initial sealing procedure, incorrect seals might emerge from the improper size of the induction sealing. Therefore accurate sizing is essential to establish the precise system required to operate a given product.

Things to Consider of Buying Induction Sealer

When you are planning to buying an aluminum foil sealer, this article elaborates from which 8 important considerations are the following for your reference.

- Type of Lids

- Cooling Ways: Air-cooling and Water-cooling

- Induction Sealer Machine Price

- Degree of Automation

- Technical Support

- Warranty

- Electrical Requirements

- Size of Factory

More details information please visit 8 Important Considerations When Buying an Induction Sealer.

How does an Induction Sealer Benefit Business

Against Tampering

The excellent sealing using an induction sealer machine protects the bottle’s contents against tampering. Because the sealing is tamper-resistant, it prevents theft. Usually, the seal is impossible tampere with without leaving a tamper-evident trail. As a result, it has the potential to reduce theft. An induction sealing machine prevents leaking since it seals the container with an airtight seal. Because of leakage proof, many customers may be attracted, increasing business earnings.

Keep Freshness

An induction sealing machine increases the product’s freshness may be preserved for a long period since it does not come into touch with air. This improves customers’ trust and in turn, improves business competitiveness. It helps preserve the safety and integrity of quality items. The containers’ flawless sealing characteristic helps to keep their contents from leaking out.Efficient

The induction sealing machine is efficient, has increased sealing capacity, produces minimum waste, and retains the visual appeal of the package. The VTOPS induction sealer machine is equipped with the most up-to-date features. As a consequence, it is capable of meeting the demands of the most demanding industrial environments. As a result, the machine offers outstanding performance, minimal maintenance costs, and high levels of operational fluency.People Also Ask

What Is An Induction Sealer Machine

An induction sealer machine is a device that is used to seal the tops of containers such as bottles and jars. These machines have the capability of sealing a variety of containers using the induction method with the non-contact mechanism.

The induction sealing machine is a particular sealing machine that seals aluminum foil by electromagnetic induction. In addition, to learn more about sealer machines, please click Sealing Machines.

What Are The Induction Sealer Machines Used For?

Induction sealer machines are primarily used in the packaging industry. The machine provide induction sealing solutions for the pharmaceutical, agrochemical, healthcare, food, beverage, and petrochemical industries. An induction sealer machine ensures that the content is protected from harm or leakage by airtightness. The machine also ensures that the content is tamper resistance.

How Does The Induction Sealer Machine Work?

An induction sealer machine employs non-contact hermetic sealing. The process is achieved by passing a bottle beneath an induction seal, generating an airtight seal. Induction sealing requires induction heating to join thermoplastic materials. It includes using electromagnetic induction to heat an electrically conducting material using eddy currents’ heat created in the item.

What kind of Aluminum Foil meets the standard?

Where to Buy SInduction Sealer Machine?

Zhengzhou Vtops Machinery Co Ltd is one of the most professional manufacturers and suppliers of packaging machines from China. We export different packaging machines and labeling machines. Please choose the item that interests you and send us your inquiry.

As a CE-certified, TÜV Rheinland Verified, Owned 40,000 m2 Processing Plant, we can supply any labeling machines you want.

Conclusion

You already know all you need to consider when selecting a suitable induction sealer machine. The primary function of an induction sealing machine is to create a seal between a cap and containers to eliminate the chances of content leaking. And also ensures that the caps are tamper-proof, help keep freshness, and promote prolonged shelf life of the contents.

In comparison to other sealer equipment, the induction sealing machine is outstanding in the safe packaging of bottles and jars. For this reason, the properties of the induction sealing machine offer sufficient justification to persuade you to get one for your business.

Above all, investing in a high-performance induction sealer machine will save you time and effort. In addition, troubleshooting the induction sealing machine is not difficult.